Metallurgical Lab

Solving Problems From the Simple to the Sophisticated

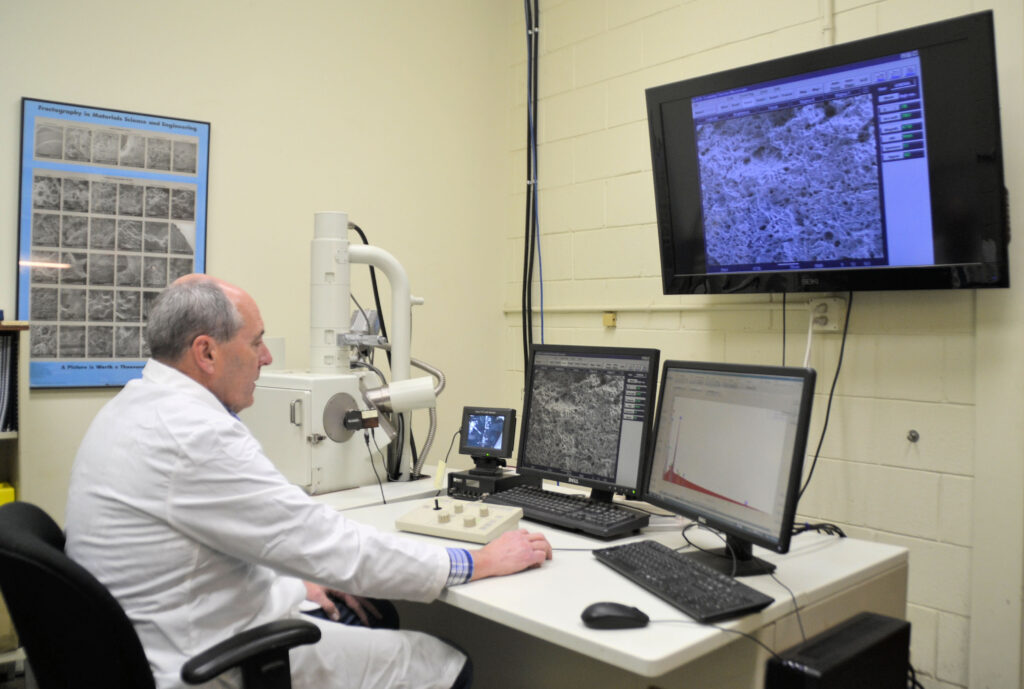

CTL combines technical consulting with laboratory testing to solve a broad range of metallurgical problems from the simple to the sophisticated. With decades of experience, the CTL team consists of materials scientists, metallographers, chemists, and engineering technicians – all working to give our clients the information they are looking for. This information includes identifying the cause of failures and corrosion problems, testing materials and parts to determine if they meet specifications and reverse engineering competitor’s products. Then, based on the lab findings, our experts can provide recommendations for corrective measures–including material applications, design changes, or improvements to instructions, warnings, labels, and specification requirements.

metallurgical analysis

Examination of your parts and materials can include macro, micro and scanning electron microscopy (SEM) examinations. Our laboratories are equipped to perform metallographic sample preparation, microstructural evaluations, hardness testing, fracture surface examinations, coating studies and corrosion analysis. Machinists and welders are on staff to section larger samples, prepare tensile samples, and fabricate test fixtures. The SEM with energy dispersive spectroscopy (EDS) and an experienced operator are also available for client rental by appointment.

DOWNLOADABLE BROCHURES

METALLURGICAL & MECHANICAL ENGINEERING

ASK THE EXPERT

Greg DuBois

Location: Columbus

Direct Dial: +1 614-824-3512