Coordinating Engineering Services Can Save Time, Money and Shorten Project Timelines

CTL Engineering offers diversified engineering and testing services to understand the project’s needs and offer the correct expertise for the challenges at hand.

One of the ways CTL provides time and cost savings to a client is through our ability to coordinate engineering services.

Coordinated services can prevent costly delays

Many municipal, private, and site civil design firms hire CTL for geotechnical services, for example, but may not think about the benefit of geophysical surveys or environmental due diligence for certain sites. These additional steps are critical on sites such as sanitary sewer and water installation along the roads, municipal infrastructures in urban areas, commercial properties such as former gas stations, strip malls, etc.

A geotechnical subsurface investigation focuses on studying soil’s physical properties to determine soil stability, bearing capacity, and parameters for foundation design in discrete select boring locations. Still, it doesn’t focus on potential adverse environmental impacts.

If, however, hazardous substances or petroleum compounds are unexpectedly encountered during construction — such as while groundwater dewatering and/or excavating — the risk of project delays, large cost overruns, and liability is much greater.

In addition, geotechnical evaluations can be enhanced by using geophysical surveys as a non-intrusive way of scanning larger portions of a site to image subsurface conditions and direct the discrete geotechnical borings as appropriate.

This is where coordinated services provide benefits to our clients. Often, when preparing a proposal, CTL’s Geotechnical group will consult with the Environmental group. A quick ‘desktop review’ can help determine potential soil, soil gas, and/or groundwater contamination. By raising flags early, CTL can suggest proactive screening of the soil while conducting geotechnical borings.

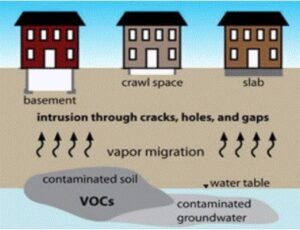

Not only is this strategy cost-effective, but it can also determine whether remedial actions, such as soil and water management or radon or contaminant vapor intrusion mitigation, will be required during construction — preventing project delays and reducing exposure and liability.

CASE STUDY ONE: Proactive Planning Eliminates the need for a Phase II ESA

Recently, CTL Engineering conducted an environmental screening during the geotechnical investigation for the City of Grandview Heights, Ohio.

The data collected confirmed petroleum contamination at some locations and also identified clean areas. CTL’s team made recommendations to manage groundwater removal and excavated soils during construction from the contaminated areas. Since the area will be developed with the city offices on the first floor, CTL also addressed potential vapor intrusion into the building during the building design and construction.

This proactive approach eliminated the need for a Phase II Environmental Site Assessment, saved thousands of dollars for the client, and reduced the project timeline.

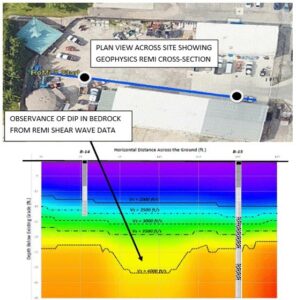

Since traditional geotechnical exploration programs provide discrete samples of the boring locations and the soil data is interpolated between the borings, CTL conducted a geophysical survey to test the soil between the two boring locations (as illustrated in the visual graph below), gathering more data. Our experts utilized Refraction Microtremor (ReMi) test methods, which model the shear wave velocity (Vs) profiles of the subsurface materials at each test location, to illustrate material characterization and its relation to the materials mass density.

In this study, the profile shown below revealed a significant drop in the bedrock level between the two borings within the footprint of a proposed building. Consequently, foundation design recommendations changed significantly. This early change prevented change orders during construction, and ultimately reduced liabilities, and avoided building failure.

CASE STUDY TWO: Construction compliance services prevent re-construction and liability

Construction observation, soil compaction, and concrete testing performed during construction are also services that, if performed early enough, can prevent much larger problems down the road. These services document compliance with construction specifications, mitigating the potential for future problems, such as settlement, pavement or foundation failures, etc.

CTL has performed thousands of materials testing projects before and during construction to ensure quality and compliance. While it is difficult to assess the cost savings of these activities, there are frequently situations where CTL testing redirects construction performance, which, if left unchecked, would have resulted in thousands of dollars of re-construction; or worse yet, damage, liability, and even loss of life if a failure occurs down the road.

Coordinated engineering services prevent delays, extra costs, and future problems

For 95 years, CTL Engineering, Inc. (CTL) has offered diversified engineering and testing services for our valued clients.

CTL’s team of experts adds value by taking ownership of the client’s project, understanding their needs, and where applicable, recommends coordinated engineering services that can be integrated for the success of the project.