Forensic Engineering Solves Plumbing Failure Mysteries

Plumbing failures are rarely pleasant. Water can cause significant damage in a short period. Additionally, leaking water pipes can allow potentially harmful contaminants into drinking water, and untreated sewage flooding a home or workplace often renders it unfit for occupancy.

Structures lost to water damage become costly liabilities, often triggering complex litigation that boils down to a simple question: Who’s to blame?

What is forensic engineering?

Answers to this and many other building failures come from the work of forensic engineering — painstakingly analyzing mishaps to identify their root causes and provide crucial clues that can help prevent the next failure. At CTL Engineering, we’ve helped courts determine the culprits in a broad range of legal cases. Here’s a look at two recent plumbing-failure cases we’ve worked on:

The overtightened toilet nut

In this case, residents came home to find water spraying from a line attached to one of their toilets, causing substantial damage throughout their home. Finding the cause started with examining the point of the plumbing failure.

The toilet’s water supply line is connected to the toilet via a plastic coupling. The coupling is economical and capable of supplying years of service if installed correctly. But it’s dangerously fragile if installed incorrectly.

The coupling must be finger tightened and then hand tightened by no more than one-half or three-quarters of a turn. Plumbers are not supposed to use wrenches or pliers because they make it too easy to overtighten the coupling — compromising its strength. The insidious thing about using a wrench here is that the damage does not show up immediately. Instead, a small crack forms and grows over time.

Eventually, the crack weakens the coupling so much that water bursts through and soaks everything. A leak could happen months or even years later, making the failure impossible to accurately anticipate.

The photo here shows water spraying from the burst plastic coupling.

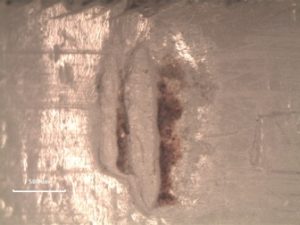

An extreme close-up, high-resolution photograph of the coupling shows marks we identified as consistent with the use of pliers to tighten it.

This kind of forensic engineering evidence can prove pivotal in water damage litigation.

The badly manufactured pipe cap

Another case also involved a failed plastic plumbing part. This incident centered on a plastic pipe cap installed to seal the plumbing temporarily in the middle of a repair job.

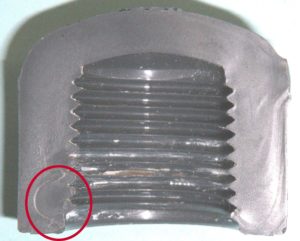

The install proved to be far more temporary than anyone expected. It split apart in less than a day after it had been installed, causing a massive water leak. The photo below shows the split cap.

The next photo shows the manufacturing defect we discovered.

To find this defect, hot melted plastic is injected into the mold. Melted plastic surrounded the mold in both directions — meeting at the point where the part had a manufacturing defect. The body of the cap contained a void that gave way under pressure, causing the spill.

Again, careful failure analysis exposed the culprit.

The forensic engineering expertise you need

At CTL, we have a team of forensic engineering experts who have analyzed a broad range of plumbing failures. If you’re involved in plumbing related litigation, we would be glad to answer your questions and provide a cost estimate for a thorough investigation. Don’t hesitate to call us.