Thermal Control Monitoring: An Important Component in Your Next Concrete Pour

By: Walt Rough, PE

Project Manager, Construction Services

Does your next construction project have mass concrete components?

Monitoring the temperature of concrete as it is poured and cured is one of the most important steps in the construction of a concrete structure.

Without the proper temperature, concrete may lose strength or durability, which ultimately affects the strength and durability of your structure.

CTL Engineering provides thermal control and concrete maturity monitoring, an important component for your next construction project – large or small – where concrete is a major component.

What is Thermal Control Monitoring, and Why is it Important?

The temperature of concrete as it cures can significantly impact its strength and durability.

The hydration process can be drastically impacted if freshly poured concrete is exposed to temperatures that are too high or too low, compromising the strength of the structure. The chemical reaction between cement and water in concrete, known as hydration, creates an exothermic reaction. The reaction can generate a tremendous amount of heat in large or massive concrete pours.

Temperature differentials refer to the difference in temperature of measured sections of a concrete mass. Temperature differentials in mass concrete structures require continuous thermal control monitoring during curing and must adhere to the thermal control plan, as outlined for each project’s specifications. The results of curing concrete can vary greatly depending on the climate. Typically, there are different concerns for projects in hot weather climates versus cold weather climates.

Additionally, if the internal concrete temperature or the differential temperature between the concrete and ambient conditions gets too high, the concrete can crack under thermal stresses due to thermal expansion and contraction.

How does Thermal Control Monitoring Work?

To ensure that massive concrete structures cure properly and reach adequate strength, contractors must pour concrete at the right temperature. If the temperature is too low, the chemical reactions that strengthen the concrete slow down significantly and will come to a complete stop. If the temperature is too high, the concrete will have early strength development. As a result, it gains less strength in the later stages. This causes lower durability of the structure.

CTL Engineering’s thermal control or temperature monitoring uses temperature probes placed at various positions in the concrete. These probes monitor the concrete temperature during the curing process. With this information, the project team can anticipate potential issues with the concrete temperate. Then, the contractor can adjust the thermal control measures used to control temperature. This, in turn, ensures the strength, quality, and durability of your structure and adherence to the thermal control plan specifications.

What is Mass Concrete?

There are no specific measurements to define mass concrete. According to the American Concrete Institute (ACI), mass concrete is “any volume of concrete with dimensions large enough to require that measures be taken to cope with generation of heat from the hydration of the cement and attendant volume change to minimize cracking.”

Examples include dams, large bridge piers and columns, mat slabs, and foundations.

Smaller structures may also have mass concrete requiring thermal control monitoring. Whether monitoring is required depends on several factors, such as type and quantity of cement, volume to surface ratio of the concrete, weather conditions, concrete placing temperatures, degree of restraints to volume changes, and the effect of thermal cracking on function, durability, and appearance.

Construction of the Hilton Hotel

Recently, CTL Engineering provided construction testing and special inspections for the new, 30-story Hilton Hotel in downtown Columbus, Ohio. The building structure is comprised of reinforced and post-tensioned concrete framing. The project specifications included thermal control monitoring for the massive concrete pile cap foundations, which will support the building frame, and mass concrete transfer beam.

The CTL team installed temperature monitoring probes within the forms before concrete placement for the massive concrete pours. The team installed the probes according to the thermal control plan developed by MJ2 Consulting. Igel also installed foam insulation boards around the forms and placed insulating blankets over the concrete. These measures helped control differential temperatures between the center and surface of the concrete.

Anderson Concrete supplied the concrete pre-cooled to help control high concrete temperatures later in the curing process. CTL tested and monitored temperatures as contractors poured the concrete to ensure the concrete met pre-cooled temperature requirements. Throughout the curing process, CTL observed the temperature monitoring probes and analyzed timely data to verify the requirements in the thermal control plan.

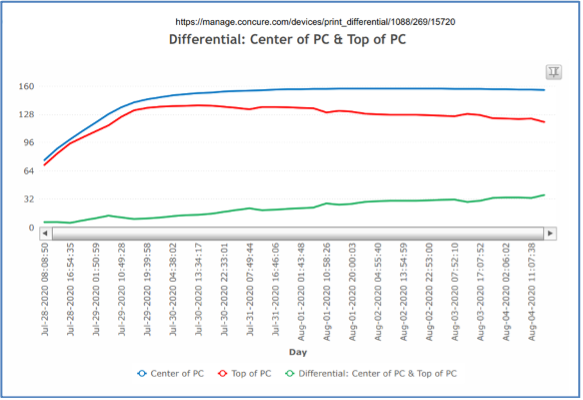

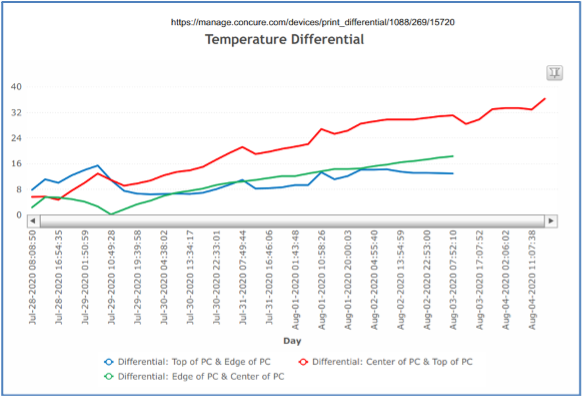

The monitoring results in the image above show the temperature differential over time at different areas of the pile cap. The amount of time for monitoring will vary for each project. These graphs also illustrate the concrete stayed within the specified range for maximum internal and differential temperatures for this project.

Learn more by Contacting CTL Engineering

In addition to the Hilton project, CTL previously conducted thermal control and temperature monitoring during the construction of large bridge piers for the Ohio Department of Transportation. In addition, CTL also offers concrete maturity monitoring.

Do you have questions about thermal control monitoring? We encourage you to contact CTL Engineering to see how our team can help you on your next project.

Walt Rough, P.E., Project Manager-Construction Services

Walt Rough, P.E. serves as a Project Manager for the Construction Services Department at CTL’s Columbus, Ohio office. He has over 17 years of experience in the construction materials testing and special inspections field. His work includes coordinating the various project activities, including subgrade investigation, compaction, foundation, reinforcing, concrete, floor flatness, masonry, and fireproofing inspections. Mr. Rough formerly served as a technician of CTL’s Construction Services Department in the Columbus Office.