Indianapolis International Airport’s Southern Parallel Runway Designed to Last

By Steve Chastain

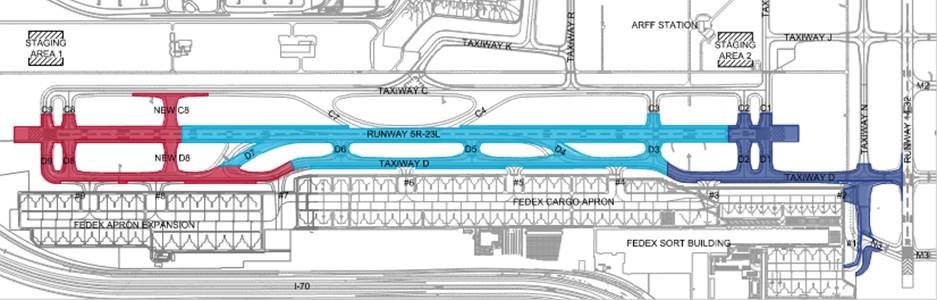

As one of the largest runway and taxiway strengthening and enhancement capacity construction projects in the country for a mid-size airport in 2022, Indianapolis International Airport’s (IND), Runway 5R-23L and Taxiway D, isn’t typical.

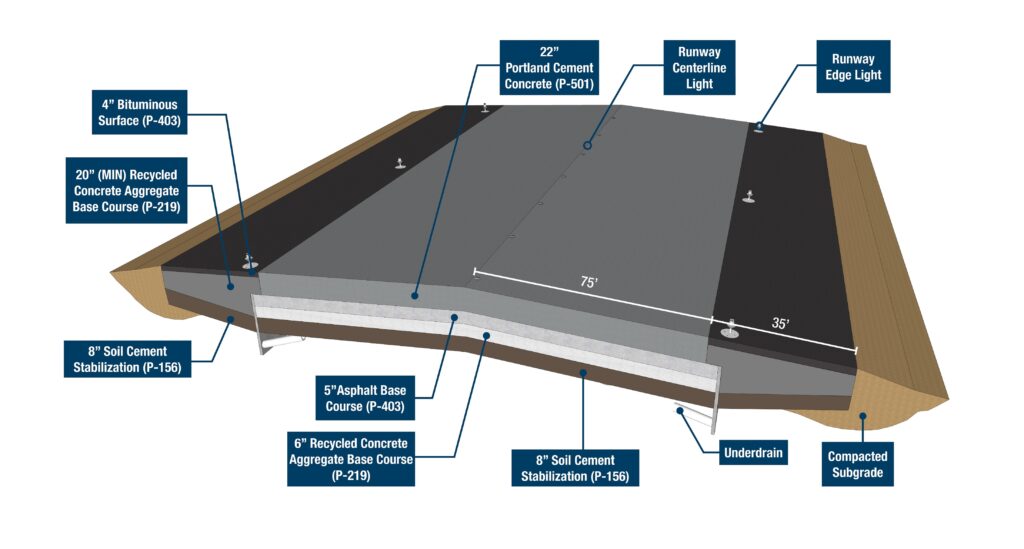

For one thing, the pavement is designed to last 30-40 years – much longer than an average 20-year lifespan. For another, it includes some of the thickest pavement sections constructed at IND, as the existing 150’ x 10,000-foot runway pavement, constructed in 1992, was not designed for the heavier planes currently using the runway.

Sustainability features are another unique aspect of this project. This includes pulverizing the existing concrete pavements to be utilized as sub-base, using carbon-reducing technologies in manufacturing of the new concrete, new LED Lights and Signs, reuse stormwater for construction, low emitting equipment, and several other sustainability initiatives.

With FedEx’s cargo business at IND reaching a record high of 1.3 million tons and 5.7 million tons of landed weight in 2021, it represented the largest volume in its 30-year history in Indianapolis. The result of this project will be a much more durable and long-lasting runway that can support FedEx’s fleet, including the Boeing B777F, one of the world’s largest twin jets. FedEx’s second-largest hub is located in Indianapolis and the reconstructed runway and taxiway are designed to handle growing demand.

To assist in the initial construction phase, the project received $56.3m in federal dollars from the Federal Aviation Administrations (FAA) Airport Improvement Program (AIP) funding. This marked the largest allocation from the 2021 federal budget and the largest in the Indianapolis International Airport’s history.

Runway Reconstruction is Indiana’s Largest Construction Project in 2022

The project – led jointly by Circle City Aviation Partners (a joint venture of Woolpert and Kimley Horn) – is a full-depth reconstruction of the southern parallel runway and taxiway at Indianapolis International Airport. CTL Engineering served as the geotechnical engineer of record for the estimated $160 million project and is now providing quality assurance testing and construction inspection as the project is built.

This is the largest runway reconstruction project ever completed by CTL Engineering. The pavement section is designed to support the large aircraft, and at 33-inches was intentionally over-designed to increase durability and resiliency and, in turn, far exceed the FAA’s required design life of 20 years for new pavement sections by providing a pavement that will last 30-40 years.

Too big of a job to complete in one year, the project will be built in 3 phases over the course of three years. With a bid of $69.5m, Walsh Construction was awarded the 2022 Phase I construction contract. While phasing a project over multiple construction seasons is always challenging, the runway and taxiway will also be open to air traffic in the winter months, meaning strict schedules were necessary to ensure that each phase was complete at the end of the construction season. Additionally, Phases 2 and 3 are being designed such that a portion of the runway can remain open in a shortened condition for a large duration of the construction to continue to accommodate FedEx’s traffic and avoid intermingling their operations with the airlines as best as possible.

Despite the many challenges of the project, CTL delivered the project on time and on budget as promised.

CTL Engineering Provides Geotechnical Services

Because of the size of the project, the design team was closely integrated, and CTL Engineering was involved in each step. In Part A, CTL proved a Preliminary Engineering Study, which provided guidance to perform the Preparation of Construction documents. Geotechnical drilling and pavement cores allowed CTL’s report to include:

- Identification, measurement, and tabulation of individual pavement, base, and subbase layer thicknesses at each boring location, from the top of pavement down to the top of the subgrade.

- Existing subsurface condition of the site including a description of the prevailing subsurface characteristics of the site, soils stratigraphy and consistency, groundwater conditions, any unusual conditions, and a summary of the existing pavement conditions.

- Geotechnical-related recommendations for the reconstruction of the proposed pavement.

- Construction considerations related to the soil and groundwater conditions and earthwork requirements and

- Geotechnical recommendations and pavement soil parameters required for pavements for pavement design including recommended CBR and soil k values for use in design.

Also during Part A, CTL had the opportunity to be mentored in the FAA’s pavement design process to further enhance our engineering capabilities and services.

During Part B, CTL provided final geotechnical engineering design recommendation services in preparation of final construction documents. CTL is also providing the Quality Assurance Materials Testing services and supplemental Construction Inspection Services.